IF:7.656: Kun Lin (etc.) High Performance and Low Thermal Expansion in Er-Fe-V-Mo Dual-Phase Alloys

Lin, K.; Li, W.; Yu, C.; Jiang, S.; Cao, Y.; Li, Q.; Chen, J.; Zhang, M.; Xia, M.; Chen, Y.; An, K.; Li, X.; Zhang, Q.; Gu, L.; Xing, X., High performance and low thermal expansion in Er-Fe-V-Mo dual-phase alloys. Acta Mater. 2020, 198, 271-280

ABSTRACT: Low thermal expansion alloy plays a unique role in high precision instruments and devices owing to its size stability under thermal shocks. However, a low thermal expansion generally produces a poor mechanical performance, such as brittleness and low fracture resistance, which is a bottle-neck for their applications as functional materials. In this study, Lin and Xing etc. demonstrate a novel intermetallic compound-based dual-phase alloy of Er-Fe-V-Mo with excellent structural and functional integrity achieved by precipitating a ductile phase in the hard-intermetallic matrix with large magnetovolume effect. It is found that the compound with 12.8±0.1vol% precipitate phase improves the alloy’s strength and toughness by one order of magnitude, while keeping a low bulk coefficient of thermal expansion (1.87±0.02 ´10-6 K-1) over a wide temperature range (100 to 493 K). The combined analyses of real-time in-situ neutron diffraction, synchrotron X-ray diffraction, and microscopy reveal that both the thermal expansion and the mechanical properties of the precipitate phase are coupled with the matrix phase via semi-coherent interfacial constraint; more importantly, the precipitate phase undergoes a pronounced strain hardening with dislocation slips, which relieves the stress localization and thus hinders the microcrack propagation in the intermetallic matrix. Moreover, the alloys are easy to fabricate and stable during thermal cycling with great application potentials. This study shed light on the development of low thermal expansion alloys as well as the implications to other high-performance intermetallic-compound-based material design.

Lin, K.; Li, W.; Yu, C.; Jiang, S.; Cao, Y.; Li, Q.; Chen, J.; Zhang, M.; Xia, M.; Chen, Y.; An, K.; Li, X.; Zhang, Q.; Gu, L.; Xing, X., High performance and low thermal expansion in Er-Fe-V-Mo dual-phase alloys. Acta Mater. 2020, 198, 271-280.

https://www.sciencedirect.com/science/article/pii/S1359645420306091

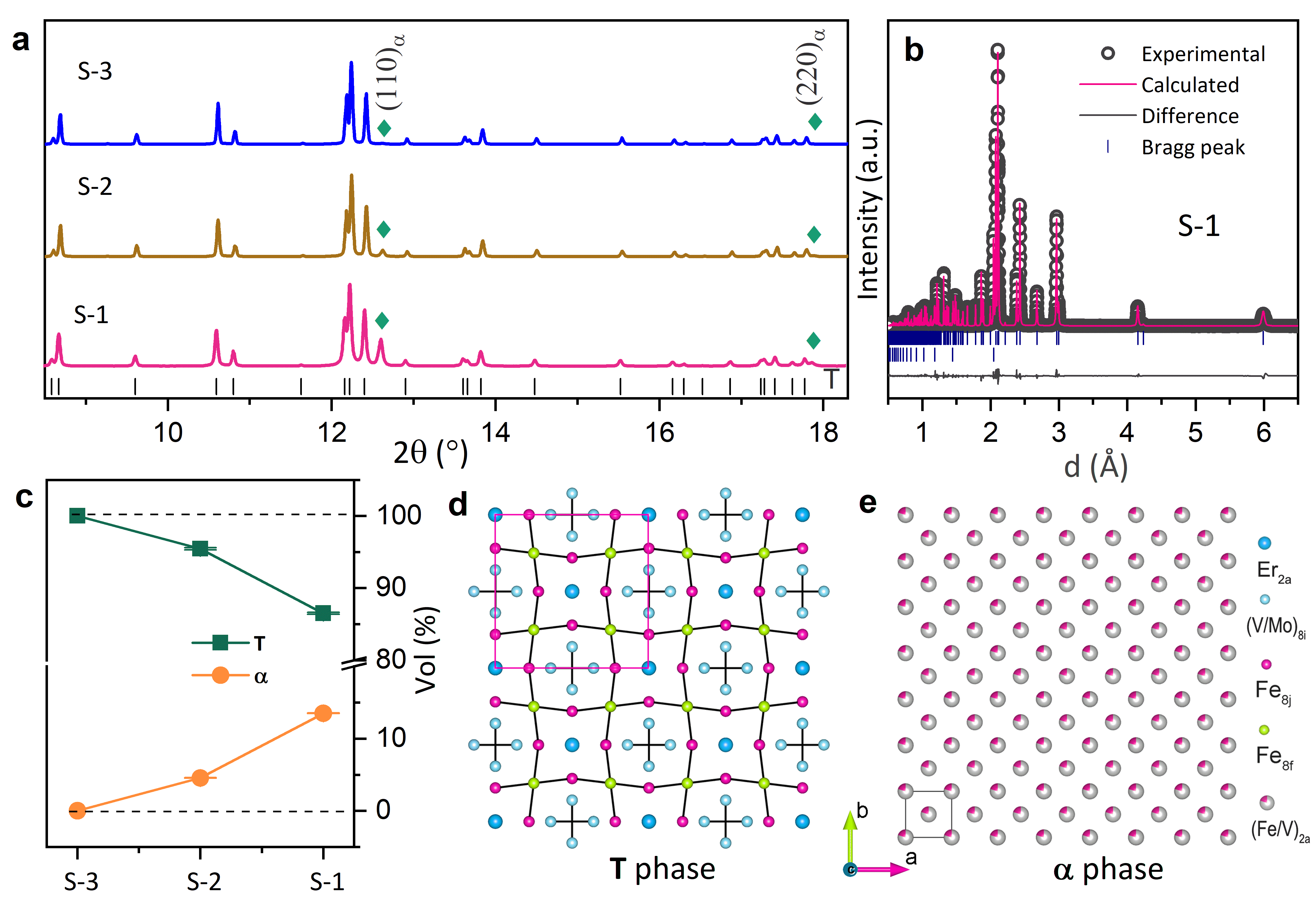

Fig. 1 Phase and microstructure of the as-synthesized alloys. (a) Synchrotron X-ray diffraction profiles for S-1, S-2, and S-3 (λ= 0.45Å). The bars at the button indicate the Bragg peaks of T phase, diamonds indicate the bcc α phase. (b) The Rietveld full-profile refinement of the synchrotron X-ray diffraction for S-1. (c) The volume fractions of T and α in S-1, S-2, and S-3 revealed via Rietveld refinements. (d,e) The crystal structures of T and α phases along the [0 0 1] direction.

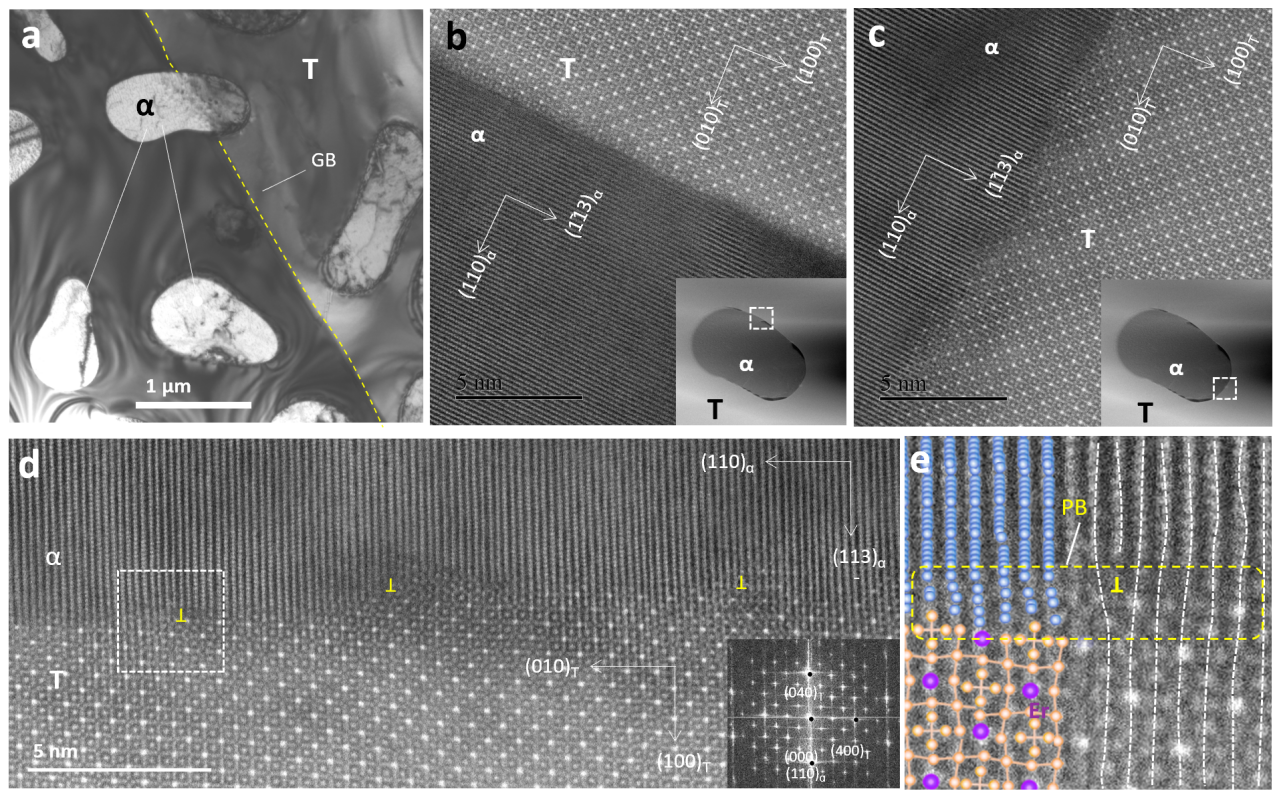

Fig. 2 (a) TEM morphology at low magnification for dual-phase alloy S-1. (c,d,e) High resolution STEM image showing the interface between T and α phases. Inset in (d) shows the corresponding FFT profile. (e) The enlarged region labeled in box in (d), which displays atomic matching between α and T phases at interface. “┴” indicate the edge dislocation. The large balls are Er, small balls are Fe/V/Mo. PB: phase boundary.

![]()

Fig. 3 A review of strength versus temperature window of low thermal expansion for existing intermetallic-compound-based metallic materials.